Table of Contents

Who are we talking about?

We’re presenting to you today a manufacturing company with several complex processes to monitor, control, and collect and analyse data from. The team is ambitious, scrappy, and highly iterative in their approach.

With a focus on the efficiency and effectiveness of the people and processes on the plant floor, they set one goal for this project: improve quality inspection.

The past situation

Initially, their quality inspection process was quite old-fashioned. Operators were manually inspecting products and jotting down notes on paper—marking the product ID and whether it was acceptable. This system had plenty of flaws. Notes often went missing or weren’t recorded correctly, leading to inconsistent data. Plus, tracking specific defects manually was inefficient, to say the least.

The use case

Before we stepped in to help, the process was like this:

- The product runs through production, which means it has a product ID.

- When the time comes, the operator takes each product, inspects it manually, and writes the ID on a piece of paper together with the verdict: OK or NOT OK.

- Depending on the workload of the operator, that data is also logged somewhere digitally… or not.

- Whatever spreadsheet they do have, it’s incomplete and messy.

The problem was that they had no way of keeping track of that key data. They had no useful information to fix and/or improve the process. Moreover, the verdict depended on the operator—what does “OK” or “NOT OK” mean? What’s wrong with the product? To what degree? Each operator had their own interpretation of what made a product “good” or “bad,” resulting in varied quality assessments.

The reality of their scrap rate was concerning. We don’t have an exact number, but for the sake of the case study, let’s say that more than half of the products from this specific line couldn’t be delivered.

The solution

Phase 1: The Wedge Scanner

In the first phase, the company’s team introduced a wedge scanner to automate product identification and we helped implement it. When a product was scanned, its ID was automatically populated in the system, significantly reducing manual entry errors. The scanner also cross-referenced the database to verify the product’s authenticity, catching any discrepancies early on and ensuring that each product was correctly identified (fx. Make sure someone didn’t take a product from another area).

Phase 2: A more efficient User Interface

Next, we focused on improving the user interface (UI) to enhance operational efficiency. We simplified the UI to reduce the number of clicks required from operators. If a product scanned correctly and was defect-free, it was automatically marked “OK”, allowing operators to focus solely on defective products. This change streamlined the workflow and minimised unnecessary interactions with the system.

We also added options for operators to specify the nature and location of defects, splitting the product into six areas for precise identification. This feature enabled operators to provide detailed defect information, improving the accuracy of the inspection process.

Phase 3: Automated system using a camera

In the third phase, we contributed to an image inspection system integrated with machine learning. The company’s team installed a camera system on the product line to take detailed images of the products as they were cut, and asked us to help with the interface and with the Ignition side of using/viewing the images. These images were processed by a machine learning algorithm (created and handled by another external consultant) running in a Docker container, which identified and highlighted defects. Operators could review these images and the algorithm’s findings, confirming or rejecting the detected defects. This hybrid approach combined automated defect detection with human oversight, ensuring higher accuracy.

The images were stored on a dedicated computer on the plant floor. The PLC would publish the image information to the front-end gateway, where it was visualised using Perspective. This setup allowed operators to see which machine (e.g., Saw #2) generated each image.

To handle the inspection process efficiently, the operators could choose from three operational modes that came from the PLC side and we had to follow:

- Manual Inspection Mode: The operator inspects each image. The process halts after an image is taken, waiting for the operator’s input.

- Bypass Mode: The process continues without considering any images.

- Automatic Inspection Mode: Images are displayed, but the process continues without waiting for operator input. Operators can monitor the process but don’t need to intervene.

On the HMI of the saw itself, they could switch between the three different modes. The selected mode would set certain tags that Ignition will use to determine how to proceed on each image. Depending on the values of these tags, we know if we need to run the external algorithm, show the image or just disregard everything (bypass mode).

In Manual Inspection Mode, we faced a challenge with the three saws running in parallel, each producing an image simultaneously. To avoid bottlenecks, we displayed the oldest image first, allowing the PLCs to wait for the operator’s response. This way, while the operator inspected the oldest image, the other saws continued working. While the products were typically ok, they still had to be inspected and approved by the operator. In many cases, the operators do that very quickly, and the line isn’t stalled.

The back end

Building a solid infrastructure and network architecture was crucial for the success of our solution. They had a dedicated network for this product line to ensure smooth communication between the cameras, PLCs, and the Ignition system. Images were stored locally to avoid bandwidth issues, and we had two Ignition Gateways that handled real-time data processing (the back-end gateway on the plant floor, in the line’s network) and visualisation (the front-end gateway in the “Administrative” network). We used MQTT for communication between back-end and front-end gateways, with the back-end handling logic and data processing and the front-end focusing on visualisation and operator interaction.

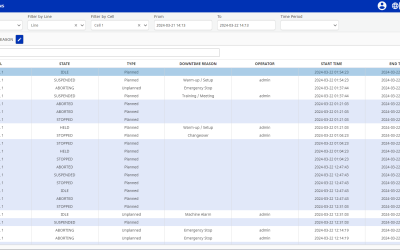

To manage data effectively, we developed a comprehensive data management system using an MSSQL database. This system tracked inspection data and linked it to existing manufacturing data, providing a complete quality profile for each product. Real-time data publishing and visualisation were enabled, giving operators and supervisors immediate access to detailed defect information.

The scalable architecture, with separate back-end and front-end gateways, provided a robust foundation for future expansions. The use of MQTT and a dedicated network ensured reliable and efficient communication.

The outcomes

Got rid of manual work and reduced human errors

The new system drastically reduced human error and variability in inspections. Automated scanning, together with the use of machine learning algorithms, ensured consistent and reliable defect detection. The streamlined UI and automation reduced the time operators spent on each inspection, allowing them to focus on critical issues. Manual data entry was minimised, speeding up the process and reducing the chances of errors.

Real-time monitoring

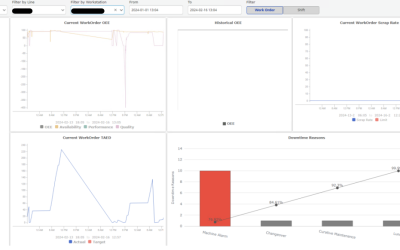

Real-time monitoring and control were greatly enhanced. Operators and supervisors could now monitor inspections in real-time, with immediate access to detailed defect information. This transparency improved decision-making and operational efficiency.

Fast feedback loops

Our collaboration with the company transformed its quality inspection process from a manual chore to a streamlined, automated system. Thanks to the easy access to data, they could narrow down the main reasons for the high scrap rate and then take action on those issues.

Essentially, we enabled a fast feedback loop from discovering a flawed product to deciding on some action.

This company is doing amazing things on the digital transformation front. And we really mean amazing – a lot of the ideas actually came from them and we just helped bring them to life.

With a bottom-up approach that has the plant floor and its people in the center, they keep showing up to solve operational and business problems every day. Powered by Ignition, their operation looks different today than it did a few years ago, and the keyword to describe it would be “innovative”.